Bulk Mining Explosives (BME) is a leading manufacturer and supplier of bulk emulsions, on-site bulk emulsion plants, packaged explosives and initiating systems to meet the needs of the mining, quarrying and construction industries.

Our portfolio is complemented by a range of services such as fly rock control, muck pile profiling and fragmentation analysis, as well as blast consulting, auditing, monitoring and software.

As a division of the JSE-listed Omnia Group, BME has leveraged considerable investment in our manufacturing base.

With the production infrastructure and supply network that we have developed over the past three decades, our clients are assured of seamless service. We also enforce a best practice environment that prioritises health and safety for all stakeholders.

Bulk emulsions and explosives for the mining industry

BME is the first explosives company to introduce cold emulsions into South African opencast mines.

Designed to deliver high quality and reliability, our INNOVEX™ brand of bulk emulsions are suitable for surface and underground applications.

They can also be transported and stored in bulk.

Packaged explosives for blasting applications

BME manufactures packaged explosives in its world-class production facility and supplies them to mining, quarrying and construction sectors across Africa.

INNOFEX™ is a combination of porous ammonium nitrate prill and fuel oil. A free-flowing blasting agent used in dry blast applications, it is oxygen-balanced to offer optimal energy and suitable for small and medium-to-large diameter holes.

INNOPAK™ packaged explosives offer reliable blasting solutions to hard rock mining, quarrying and construction applications. The product range provides various high-energy options and is available in different lengths and diameters or as a combo pack.

Technical services for mining applications

BME provides a wide range of technical services from routine blast monitoring using innovative equipment and software to advanced consultancy and optimisation projects.

Our leading design software, including BLASTMAP™ III, and our AXXIS™ Digital Initiation System provide the advantage in achieving cost saving initiatives in blasting and improved efficiencies.

Examples are:

- Reduced ore dilution and finer fragmentation for increased mineral recovery and higher plant throughput rates

- Improved wall quality and potentially steeper walls for reduced waste mining and longer life of mine

- Up to 25% higher rates of ore exposure using effective timing designs and accurate AXXIS™ electronic detonators

- Single-pass multiple seam mining using advanced timing designs and AXXIS™ electronic detonators

Down-the-hole (DTH) bulk emission explosives

BME’s DTH service delivers high-quality, reliable bulk emulsion INNOVEX explosives to blast holes and pump speciality products to achieve improved and consistent fragmentation.

Clients can also make use of our wide range of initiating systems and our market-leading AXXIS™ electronic detonation system.

Blast quality can be further enhanced by using BME’s BLASTMAP™ III software.

Blast initiating software

BME provides a wide range of technical services from routine blast monitoring using modern equipment and software to advanced consultancy and optimisation projects.

Our leading design software, including BLASTMAP™ III, and our AXXIS™ Digital Initiation System enable you to achieve higher blast cost savings and improved efficiencies.

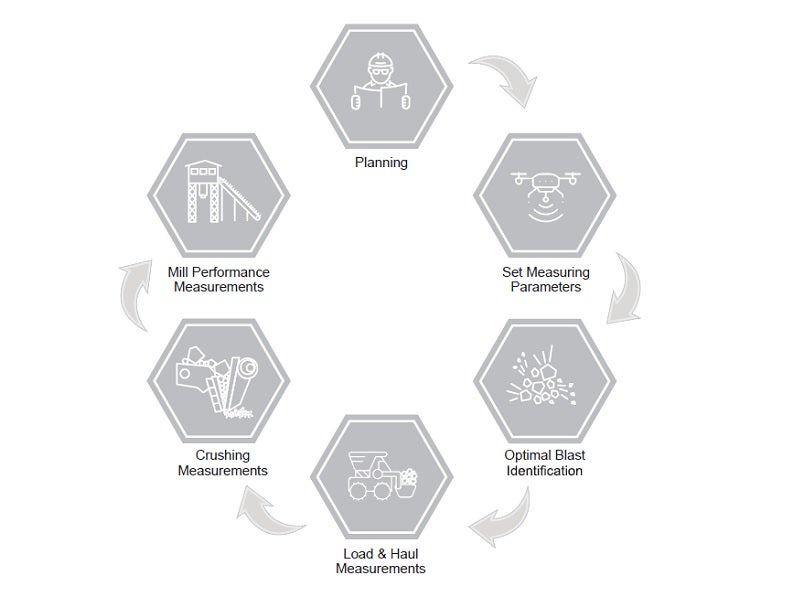

Mine-to-mill optimisation services

BME’s exclusive mine-to-mill (M2M) optimisation service delivers benefits across the mining value chain such as reduced costs and increased downstream productivity.

Blast designs can be optimised to achieve the necessary fragmentation, blast movement and muck pile shape while optimising loading, crushing, and milling rates.

Our M2M services offer an extensive view of the mining process in consultation with plant and mine personnel, which enables optimised systems and refined management of downstream costs.

About BME

Formed in 1984, BME operates in 17 African countries and has legal entities in Indonesia and Australia.

Together with Protea Mining Chemicals, we form the mining division within the Omnia Group. The Omnia Group is a diversified provider of specialised chemical solutions used in the mining, agriculture and chemicals sectors.

Based in Johannesburg, South Africa, Omnia has been in business for 61 years and has operations across Africa, Australasia and Brazil.