Eka Software Solutions is a leading provider of the latest innovative software products used to optimise stockpile management and bulk material handling in the mining industry.

The company’s Stockyard Management solution is a cutting-edge automated technology developed with a specific focus of meeting the unique requirements of raw material and bulk commodity businesses. This solution offers a comprehensive suite of advanced tools and functionalities to effectively manage and streamline bulk terminal operations.

Eka Stockyard Management solution emphasizes visibility by providing robust monitoring and reporting capabilities, it empowers organizations to gain deep insights into their bulk terminal operations. This level of visibility enables organizations to make well-informed decisions and exercise precise control over various aspects of their business, leading to enhanced operational efficiency and improved overall performance.

A standout feature of the Eka Stockyard Management solution is its operation execution. Through the strategic utilization of automation and advanced algorithms, the system operates autonomously, optimizing throughput to its maximum potential.

This ensures the efficient and seamless execution of critical tasks such as bulk material handling, storage, and transportation. By minimizing delays and bottlenecks, this autonomous capability contributes to increased productivity, reduced operational costs, and enhanced overall efficiency.

In addition to these key features, the Eka Stockyard Management solution encompasses a range of advanced functionalities designed to address the specific challenges faced by raw material and bulk commodity businesses. It provides comprehensive inventory management, precise quality tracking, and accurate location monitoring. Leveraging the power of advanced technologies like RFID (Radio-Frequency Identification) and seamless data integration, it enables real-time tracking and management of inventory, ensuring accurate quantity and condition monitoring.

Eka’s Stockyard Management solution stands at the forefront of technology in the industry. By seamlessly integrating automated functionalities, optimizing throughput, and enhancing visibility, it empowers raw material and bulk commodity businesses to achieve operational excellence, maximize productivity, and drive sustainable growth in their respective domains.

Let us explore more about the intricate features of the solution.

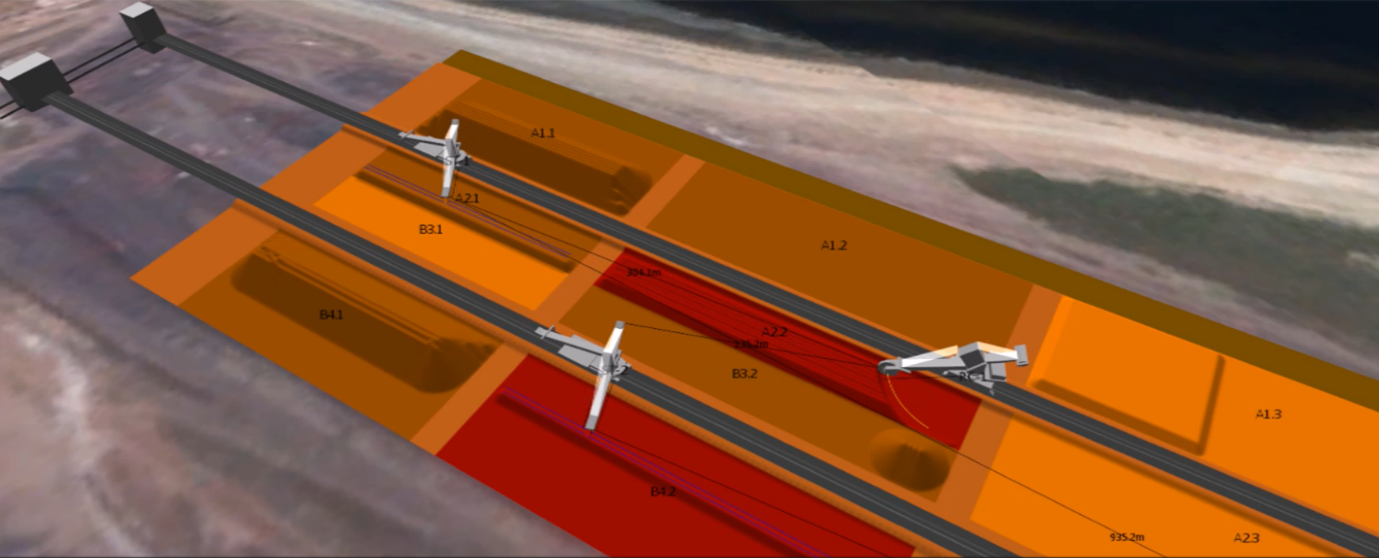

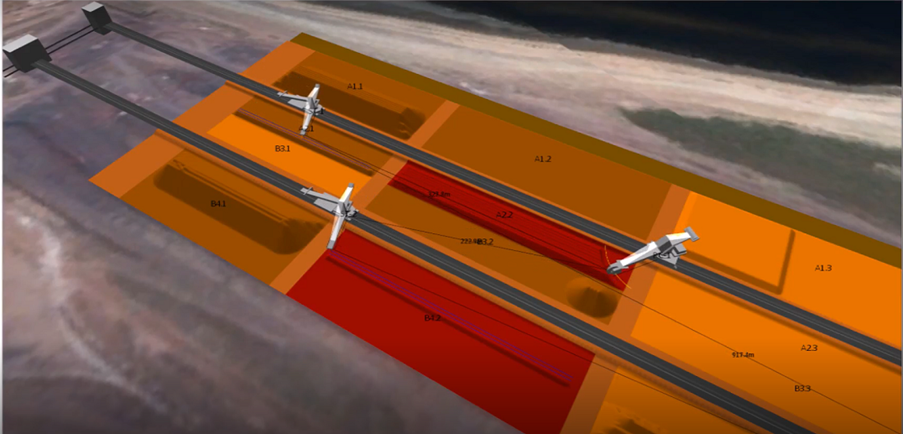

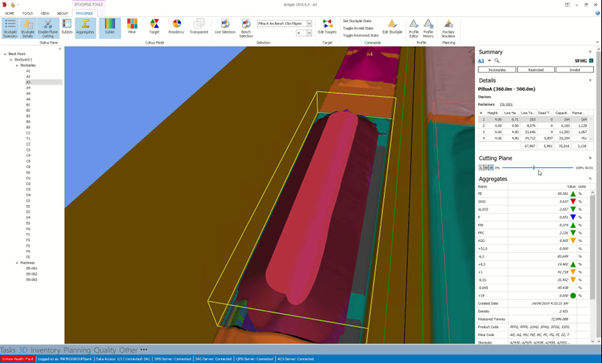

Ensure machine protection with 3D modelling anti-collision

Eka Stockyard Management solutions helps enhance stockyard management with automation, allowing seamless operations across bulk commodity handling sites. The solution also enables quality tracking and large machines to work closer together while preventing collisions.

- Eka Stockyard Management prevents collisions with user-defined exclusion areas for personnel safety. Enterprises can now optimize their usable workspace using precise 3D closest-distance calculations.

- Companies can reduce faults and foster efficiency with intelligent instrument handling.

- The solution also facilitates safe operating procedures with interlocked remove from service functionality.

Predict machine interaction to avoid collision

Enterprises can now minimize collisions with forecasts using intelligent simulation systems that precisely determine machine operations.

- The solution adjusts and prioritizes operations using rules engine.

- The autonomous machine mitigates interactions and ensures non-interference with other entities or systems.

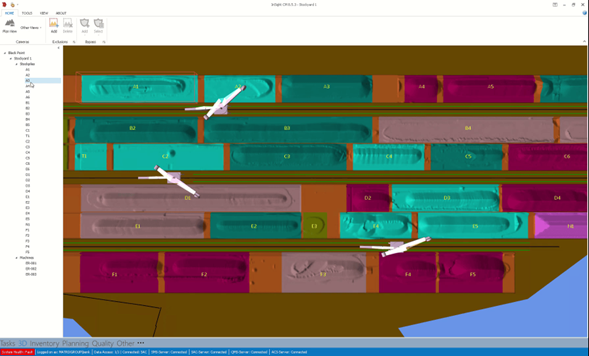

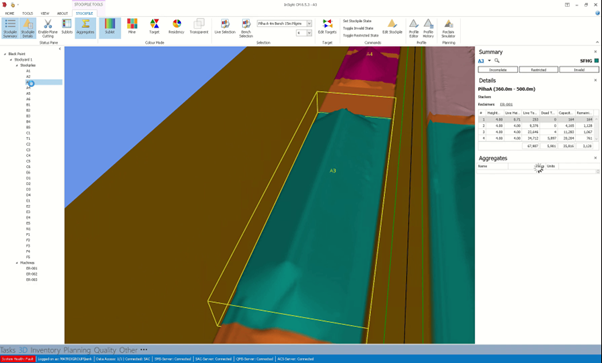

Boost the capacity of stockpile and yard

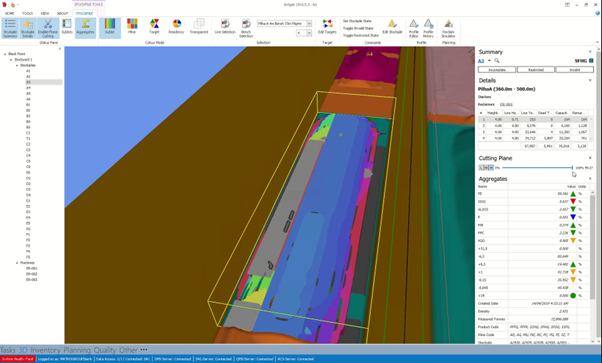

The real-time system engineered for 3D control facilitates enhanced stacking and reclaiming performance, thereby enabling businesses to achieve superior operational efficiency.

- The solution measures the automation and stockpile reclamation based on parameters such as performance, capacity, and quality requirements.

- Using advanced 3D modelling and control techniques, businesses can improve upon their stacked stockpile shape and reclaim speeds.

- Businesses can make spontaneous error-free changes using our solution’s intelligent pattern and infill analysis.

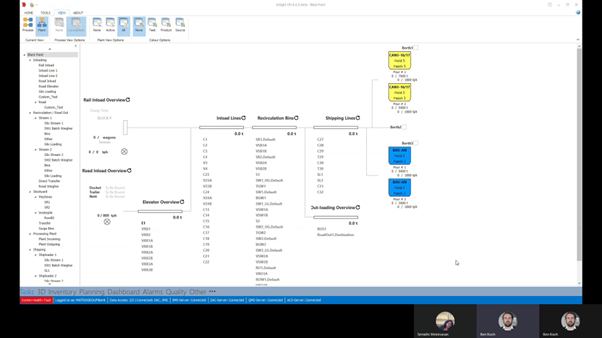

Optimize operations and efficiency

Automate plant performance, improve product integrity, uniformity, and production efficiency with real-time visibility into all operations using a comprehensive reporting suite.

- Oversee comprehensive logistics operations encompassing the reception, warehousing, and distribution processes across multiple transportation modes, including trucks, trains, and ships, while implementing advanced interlocking systems and optimized initiation protocols to mitigate operational delays.

- Advanced feed control techniques help enhance plant throughput.

- Ensure delivery to specification with automated blend management.

Enhance your Delivery Forecasting

The 3D stockpile quality model ensures control upon stockpile grades.

- Monitor the material’s quality through per-sample lot tracing during its transportation and blending within a terminal.

- Perform a comprehensive assessment of the 3D positioning of a stock and its corresponding quality indicators.

- Utilize advanced planning and simulation techniques to achieve exceptional precision in forecasting quality outcomes for forthcoming operations.