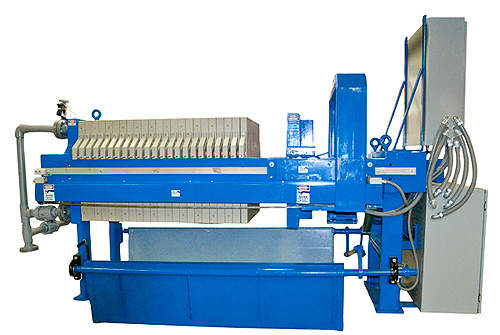

ErtelAlsop’s EA-series filter presses are among the most efficient and cost-effective means of liquid / solid separation for solution filtration or sludge volume reduction. Our presses are sized from 102mm to 1,500mm with press capacities ranging from 1ft³ to over 350ft³.

ErtelAlsop filter presses for mining

- Engineered and manufactured in the US

- Six year unconditional warranty on press frames

- The largest selection of filter plates and filter cloth

- Full service laboratories in Kingston, NY

- Assistance to optimize productivity and/or reduce your cycle times

- Rental lab presses available to perform on site testing

- Technical sales representatives are strategically placed to service you

Filter presses designed for performance

At ErtelAlsop we design and manufacture our filter presses to meet your specific needs. Our engineers will work with you to design and manufacture the optimum piece of equipment or system, with a specific focus on quality, productivity improvement, cycle optimizaation, cost reduction and safety.

Our filter presses include fast-acting hydraulic systems, uniform fill manifolds, safety lanyards, reverse core blow capabilities, and a wide range of options including a variety of construction materials and coatings, thorough wash capabilities, and PLC-controlled automation for drip trays, plate shifting, cloth washing and many other features.

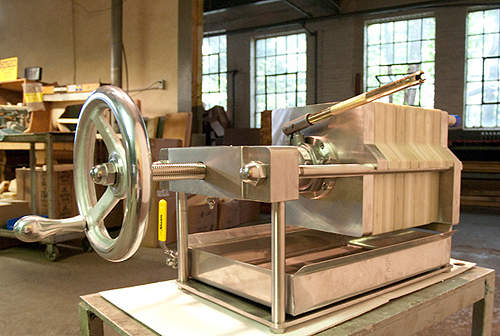

Laboratory and pilot scale filter presses

Sizing of full production filter presses often require laboratory pilot testing to evaluate the filtration characteristics of your slurry. These tests are also valuable tools for selecting filter media, evaluating chemical conditioning when required, and troubleshooting current dewatering issues.

ErtelAlsop’s lab filter press may be used for cake recovery, low solids recovery from precipitations (such as Merrill-Crowe Process) or clarification. The plates are designed to also accommodate cake washing, if required.

ErtelAlsop laboratory and pilot filter presses can be used for lab analysis and/or small batch production. These units are available for sale or rental.

Filter press standard features

- High strength carbon steel skeleton

- 304 stainless steel side bar wear strips

- Schedule 80 PVC head connections

- Four corner discharge porting

- Caulk & gasketed recessed polypropylene plates

- 32mm cake thickness

- Manual hydraulic closure system

- Chemically resistant painted framework

- Six year framework warranty

Filter press optional features:

- Stainless, aluminum, carbon steel, FRP or CPVC head connections

- Semi-automatic or automatic bombay doors

- Feed pumps: air operated diaphragm (AOD)

- Automatic pump controller

- Blanking plate

- Thorough wash capability

- Expansion capability

- Alternating discharge (1B & 3B)

- Automatic air / oil hydraulic closure system

- Electric hydraulic closure with PLC controls

- Uniform fill manifold

- Cloth washers

- Cake washing

- Cake carts or chutes

- Plate shifter

- Leg extensions

- Elevated platforms

- Safety gates

- Safety lanyard

- Safety light curtain

- Splash curtains

- Cake thickness from 20mm – 50mm

- Membrane water squeeze system

Filter press plates

Plates of every design- Recessed Chamber, Plate and Frame and Membrane Squeeze, are available in all sizes. Plates can be gasketed or non-gasketed, center or corner feed, and constructed in polypropylene, PVDF, stainless steel, Polypropylene Membrane on Polypropylene plates or other materials.

Filter press media

At ErtelAlsop the type of filter media chosen is based on your specific operating conditions, the performance required by the filtering media, and criteria given to us by you and/or by sample processing we do in our lab of your slurry.

Filter media is constructed from woven and nonwoven materials, and comes in a variety of different materials including:

- Polypropylene

- Polyester

- Nylon

- Teflon

- Cotton

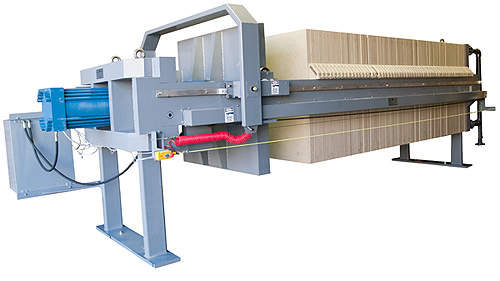

Filter press closing mechanisms

With 100 PSI and 225 PSI designs, ErtelAlsop has a closing mechanism that will fit your needs. From manual operation with an air/oil hydraulic closing system to a semi or fully automatic electric hydraulic system with PLC controls, ErtelAlsop presses are simple to use and require little training time.

Filter press plate shifter

ErtelAlsop’s mechanical plate shifters move individual plates along a stainless steal wear strip allowing rapid discharge of the dewatered cake between the plates. Plate shifters are available in semi-automatic or full automation.

Filter press media washers

Care and maintenance of the filter media is a very important factor influencing the performance of the filter press. The filter media is the initial barrier that separates solids from liquid; therefore, the filter cloth must remain porous to provide high filtration rates.

An automatic media washing system can be added to any ErtelAlsop plate shifter system. Washing the media at regular intervals not only improves the filter presses performance but prolongs the working life of the media as well.