The Galvanizers Association of Australia (GAA) conducts research and compiles case studies in corrosion protection and hot dip galvanizing of steel. The organisation also stands on various Australian Standards committees for galvanizing and related industries.

GAA provides free technical publications and information on all aspects of hot dip galvanizing, including the process, application, durability, design and painting of hot dip galvanized steel.

It conducts free informative seminars for engineers, fabricators and designers around Australia. The GAA also carries out inspections of hot dip galvanized products with qualified and experienced personnel.

Hot dip galvanizing process for steel treatment

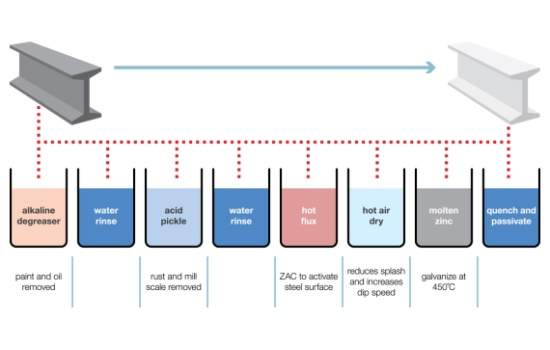

The hot dip galvanizing process starts by suspending steel articles and dipping them into a series of cleaning baths. Once clean, the steel is lowered at an angle into a bath of molten zinc. Immersing the steel at an angle allows air to escape from any vented tubular shapes or pockets in the design and permits the molten zinc to displace the air.

The steel reacts with the molten zinc to form the galvanized coating. After being withdrawn from the liquid, the final step is a quench to promote passivation of the zinc surface.

Structure of galvanized steel zinc coating

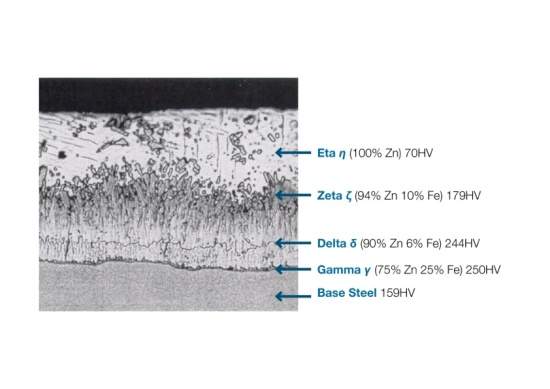

Formation of the galvanized coating on the steel surface is a metallurgical reaction, where the zinc and steel combine to form a series of hard intermetallic layers.

The outer layer is typically 100% zinc, which covers the surface after withdrawal from the molten zinc bath. The gamma, delta and zeta alloy layers are all harder than the base steel they are metallurgically bonded to, which gives hot dip galvanizing significant abrasion-resistance.

Unlike paint coatings, the galvanizing process naturally produces coatings on the corners and edges of the dipped item, which are at least as thick as the rest of the coating.

Specification of hot dip galvanizing

AS/NZS 4680 is the Australian / New Zealand Standard for hot dip galvanized (zinc) coatings on fabricated ferrous articles. It specifies the requirements of the coating and includes information on coating mass and thickness, appearance and freedom from defects, as well as suitable repair methods.

Inspecting galvanized steel is a simple process. Zinc will not adhere to or react with unclean steel, therefore a visual inspection of the product effectively provides an assessment of the coating quality.

Thickness is usually tested using a magnetic thickness gauge. The testing and sampling requirements are contained in the appropriate specification for the product (AS/NZS 4680 and AS 1214).

Surface, abrasion and corrosion protection for steel

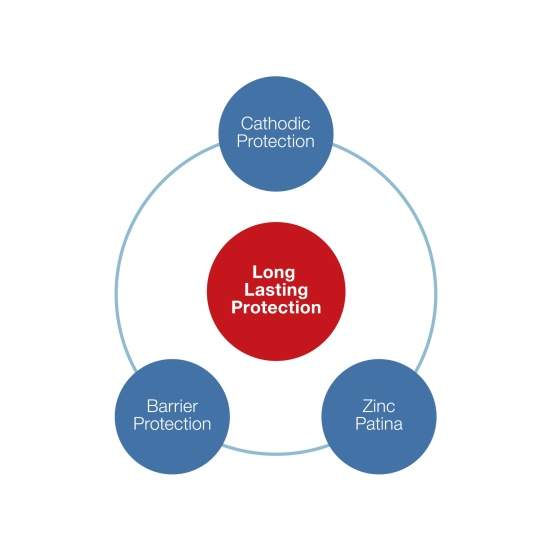

The GAA recommends a hot dip galvanized coating as it uniquely provides three types of steel protection. Firstly, the galvanized coating completely covers all steel surfaces, acting as a barrier protecting the material from the surrounding environment.

Secondly, the galvanized coating cathodically protects the steel from coating imperfections caused by accidental abrasion, cutting, drilling or bending.

Finally, the zinc patina develops over time, is insoluble and passive, which slows the corrosion rate of the zinc. The zinc patina is a critical part of the galvanized coating’s longevity and requires natural wet and dry cycles to form.

Durability of hot dip zinc coatings

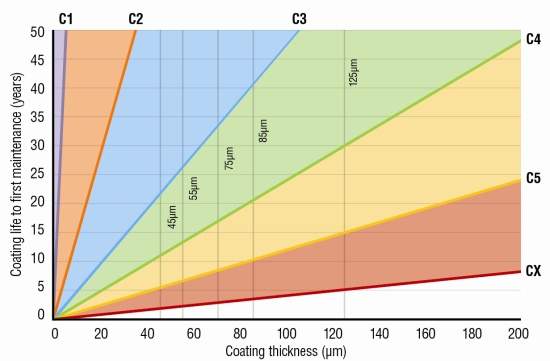

Hot dip galvanizing has proven to be more durable and predictable than all other steel protective coatings in the Australian atmosphere. Its excellent performance is due to its inherent corrosion-resistance, high-tolerance to mechanical damage and inertness to the high UV levels throughout Australia.

The life of a hot dip galvanized coating is proportional to its thickness, which is normally a function of the article’s steel thickness.

Initial and lifecycle cost benefits of hot dip galvanizing

Hot dip galvanizing has a low initial cost and is nearly always the cheapest long-term solution for corrosion protection of steel. The GAA has a micro-site, where users to calculate the initial and total life costs of more than 30 other corrosion protection systems against hot dip galvanized steel.

Based on the information the user provides, the Life-Cycle Cost Calculator will generate a customised report detailing all estimated costs associated with maintaining the structure over the desired project service life, including the time value of money.

Painting a hot dip galvanized surface

Painting of hot dip galvanized steel is sometimes required for decorative purposes, to provide an identifying colour or enhance the service life of the article.

The GAA can provide guidelines that direct specifiers and applicators to recommended paint systems and advice on surface preparation, as well as application practices that will provide a durable paint finish over galvanizing for a particular application.

Where a paint or similar type of layer is to be applied to the galvanized coating, the operator should be advised at the time of order.

Contact the Galvanizers Association of Australia for more information on all aspects of hot dip galvanizing in the mining and resource industry, or training conducted by professionals.