Glinik provides drilling tools and solutions for a variety of applications, including energy (oil & gas, geothermal), minerals (rare earth minerals, copper, lithium, sulfur, gold, lignite, coal) mining, quarry, geotechnical & construction, HDD (horizontal directional drilling), and other drilling sectors.

A European leader with extensive industry experience, our pride and expertise in this field have been built on a 140-year history of continuous improvement and technology development.

From humble beginnings to current shape, Glinik has always been guided by innovation, superb workmanship, passion for drilling tools perfecting and tailoring them to customers’ requirements. Our history reflects heritage-driven pursuit of learning, development, and the need of mastering drilling tools for our customers worldwide.

Wide mining product portfolio and a proven track record

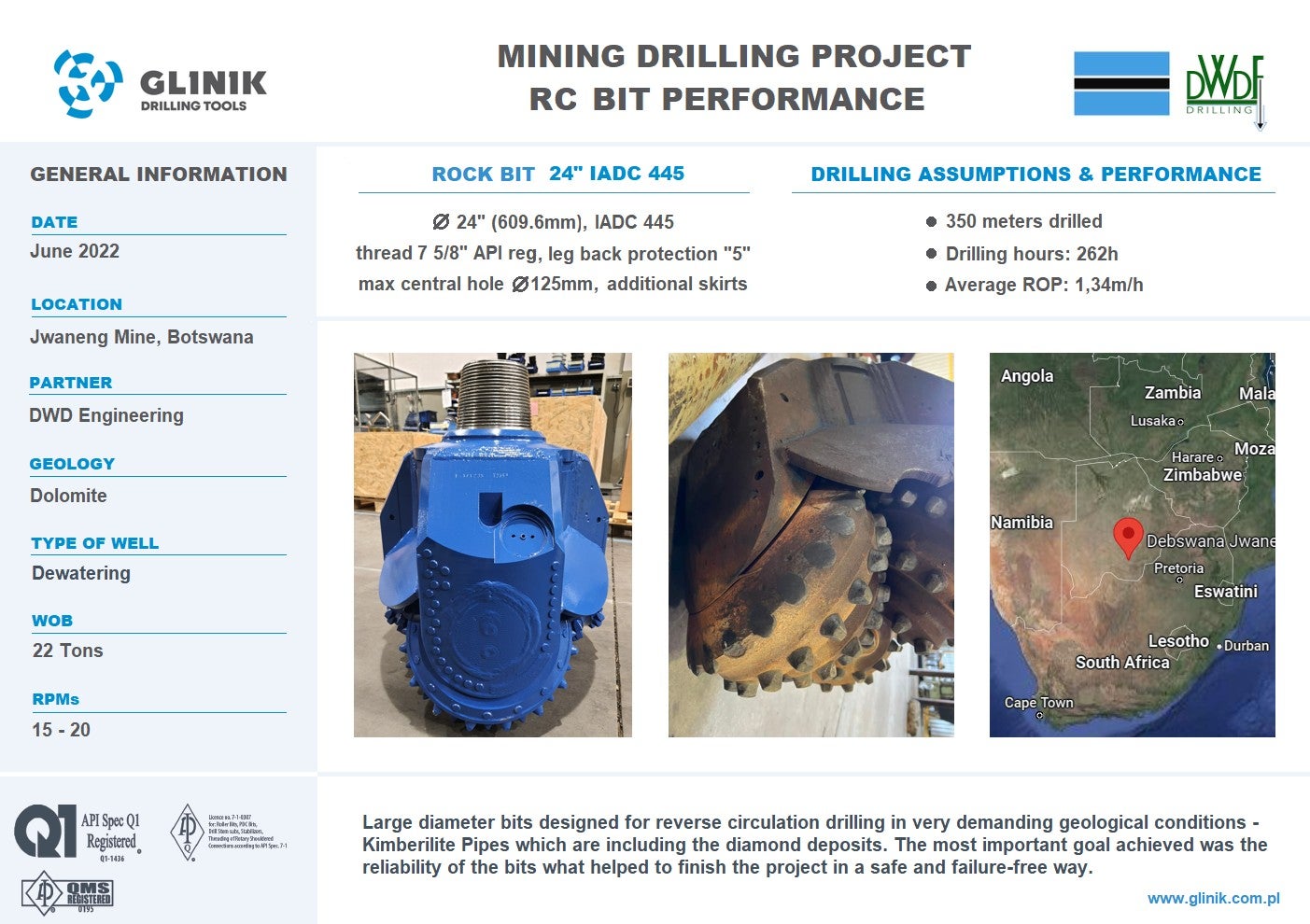

Glinik provides field-proven Roller Cone & PDC drill bits & hole openers for various mining applications, including but not limited to: minerals mining, dewatering & metane removal processes, geotechnical & construction works, civil engineering drilling and mining. Our Team delivers products to customers across the globe.

Performance data collected throughout the years of successful projects all over the world identified our expertise in meeting specific challenges of various drilling sectors.

As a result, GLINIK always takes time to listen to our Customers’ voice to address theirs need effectively and approaches each project with utmost care. Because we are willing to know what matters for the drillers.

Cutting-edge drilling solutions

GLINIK core portfolio comprises: Roller Cone (RC) bits with MT and TCI cutting structures and various dedicated designs of Fixed Cutter PDC (Polycrystalline Diamond Compact) products tailored to project’s lithology and hole openers of various types for toughest drilling.

For extended lifetime they are all equipped with wear-resistant hard facing, premium quality bearings for best bit’s performance and trouble-free operation. Effective flushing of cutting structure and bottom of hole prevents them from balling.

GLINIK hole openers are designed to work in most difficult mining conditions. Their robust, welded or exchangeable arms structures make them ready for any challenging mining conditions.

Innovation and sustainability

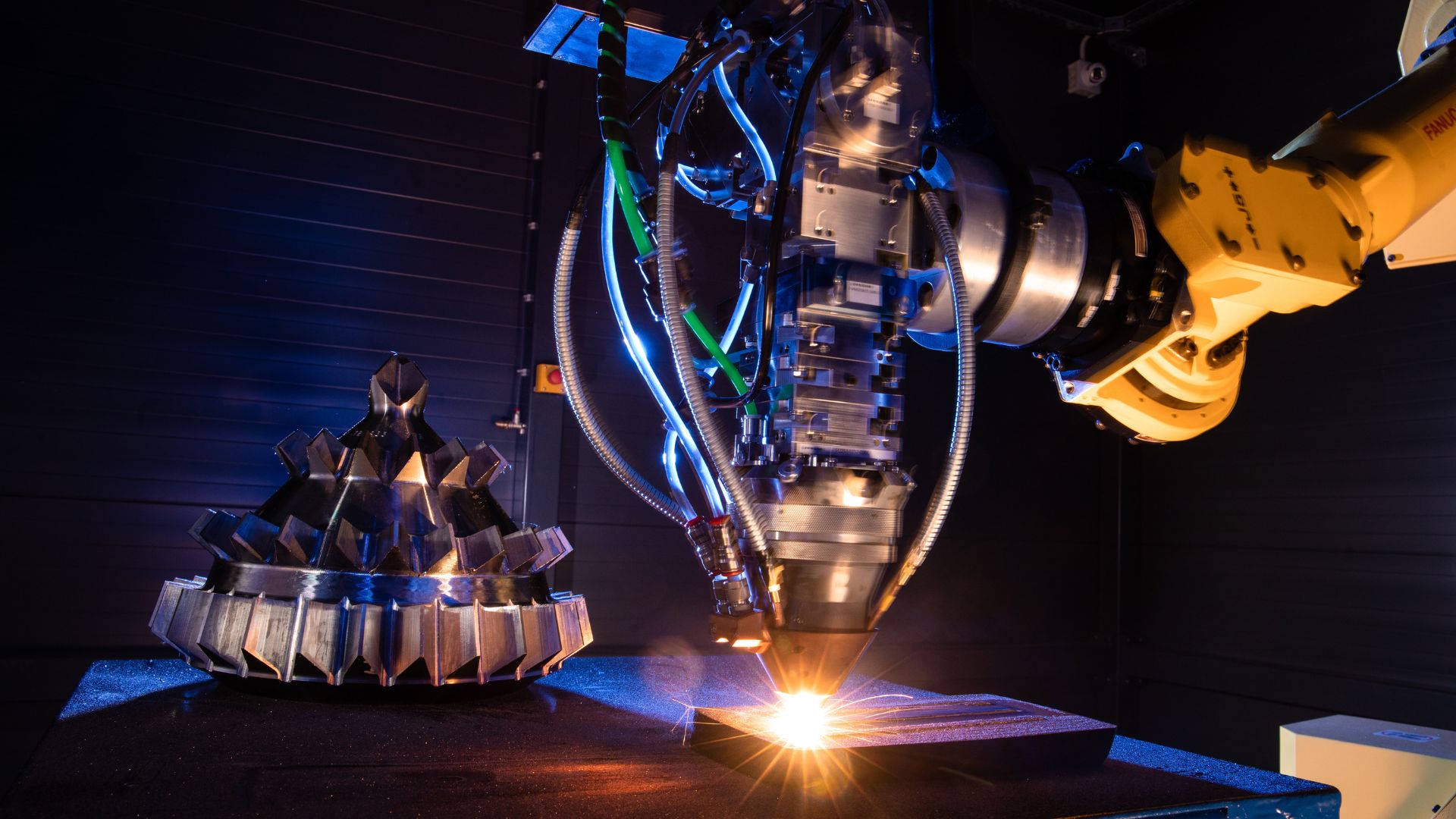

Glinik’s Engineering Team consistently leads advanced research and development projects, enabling continuous product innovation in the field of design and the implementation of cutting-edge technological solutions.

The most successful ones are used in our products enhancing their performance, abrasion resistance and lifetime expected by the most demanding customers. One of the recently developed solutions being introduced to the market is our LaserCTM technology, which delivers exceptional and unparalleled results in abrasion resistance, directly integrated into our premium drilling tools.

LaserCTM technology utilizes solutions derived from Laser Metal Deposition (LMD) technology applied to various steel types. It is worth noting that LaserCTM technology is also offered as an external service by our company.