We at IFE bulk have been dealing with the construction of machines for bulk material handling for more than 70 years.

Today, we are one of the world’s leading manufacturers of vibroconveyors, screening machines and magnetic separators for use in mines, foundries, iron and steelworks. Moreover, our machines are used in the coal, recycling, waste, and the sand and gravel industry.

Through continuous improvements, new developments and various innovations we could prevail ourselves in the world market and were able to form our reputation as a reliable and qualitative partner, standing for handshake quality.

Technical and manufacturing knowledge, in addition to our extensive expertise in process and application engineering, contribute to solid growth and guarantee high-quality results for our customers. We do not let our customers down and react quickly and reliably to their requirements and always keep our word.

We are situated in Lower Austria and from there supply the whole world with the help of our international distribution network with partners from 35 countries. This means that sales, service and spare parts are globally available at almost any time and fast reactions are guaranteed.

Our company is well known for the longevity of our machines. The lifecycles of the machines of more than 15 years at over 8,000 operating hours a year speak for themselves!

Every machine undergoes a trial run before delivery, to ensure that it meets our standards.

Vibroconveyor technology

Transporting bulk material to the right time and place is crucial for a proper production process.

Our company provides reliable, long-lasting, low-maintenance and high-efficiency vibratory conveyors with electromagnetic drives, unbalanced motors or exciter drives. Dosing units, pan and tube feeders, guide spring conveyors, bin dischargers, spiral elevators and other special equipment meet our customer’s expectations in bulk material handling.

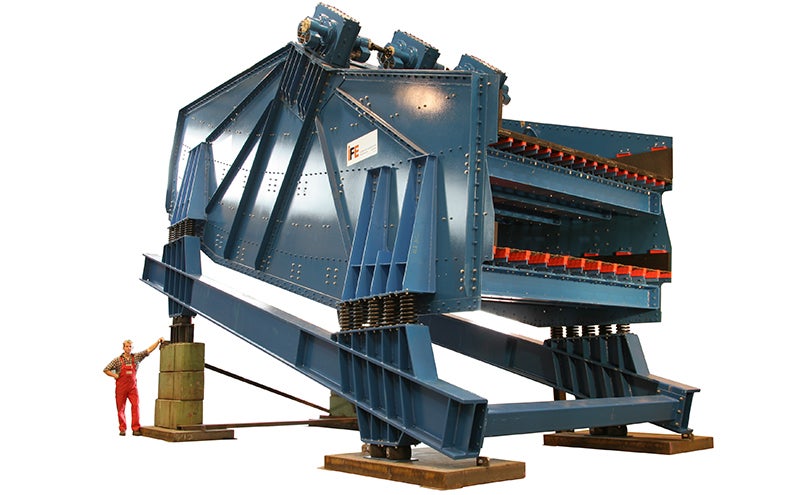

The IFE Heavy-Duty Vibrating Feeder, for example, can be used with various materials, such as chrome and iron ore. Its infeed capacity varies from 1,000t/h to 5,000t/h and can be adapted to reflect customer specifications. The robust construction makes the machine highly reliable and keeps maintenance costs low.

Screening technology

We at IFE provide innovative solutions for the separation, screening and classification of various compounds.

In addition to conventional linear and circular motion vibrating screens, our company offers special screening machines, which significantly reduce clogging and are suitable for use with material that is more difficult to screen.

Our product range includes flip-flop, banana, dewatering or underwater, waste, shake-outs, sizers or tailored screen solutions. Our mining screens are suitable for wet and dry applications.

Parameters, such as grain shape and size, humidity, output and screen cut size can be individually determined by the client.

The Heavy-Duty Grizzly Feeder can withstand harsh industrial use and is capable of processing up to 5,000tph. Although the feeder handles high-capacities it requires low maintenance efforts.

Sizer and Circular Vibrating Screens are suitable for processing crushed limestone and dolomite. This combined solution provides high screening efficiency by quick fines removal. It is a flexible solution in a compact design.

Magnetic technology

Separating through properties is a clean and effective solution. Magnets can be adjusted to suit specific requirements in inline and overband cross-belt applications. In addition, we provide specialised magnets for the separation of non-ferrous from ferrous metal in a compact, yet effective, way.

IFE provides a comprehensive portfolio of magnetic applications, including:

- Lifting magnets (electromagnetic or permanent magnetic)

- Overband separators

- Eddy current separators (centric or eccentric)

- Magnet drum separators

- Wet drum separators

- Roll magnetic separators

- Plate magnets

- Demagnetising coils

- High-intensity separators

System Technology

To optimise the production process and find an economic solution for individual tasks we provide all of our machinery in one package.

Screening, separating, conveying solutions can be perfectly coordinated to improve efficiency.

Our system solutions also provide constant high-quality performance.

Material Testing

For clients that want to process a material they have little experience with, we offer test-runs to identify the ideal method to screen, classify, separate or convey the material. Clients simply submit a sample and our experienced technicians will provide a tailored solution. Further information can be found on our website.

Development of IFE

IFE was founded more than 70 years ago as an institute for research and development. Starting with the set-up of an own production department, IFE continued to develop steadily over the years. As a manufacturer of components for the active handling and conveying practice, our company has consistently focused on high-quality and related economic success.

Innovative developments, such as flip-flop screens, hard material separators and waste screens offer extensive package solutions for problems experienced in the field of material handling. Today, IFE is among the worldwide leading suppliers of electromagnetic and electromechanical vibratory conveyors, screening machines and magnetic separators.

Through our international distribution network, we are represented in nearly all European states, as well as Japan, Taiwan, South Korea, China, Mongolia, Brazil, USA, Canada, New Zealand and Australia by our partners.