Kram Engineering was established in 1996 and specialises in wear resistant materials for the mining, petrochemical, power generation and cement industries.

Kram’s array of products and services comprises the following:

- Supply and installation of cost-effective solutions to abrasion problems

- A range of ceramic lined hydro cyclones

- Competent technical design and sales personnel

- On-site installation service and on-site briefings

- CAD design facility for process equipment

- Excellent after-sales service

The company is B-BBEE compliant and forms part of the Anglo American Zimele initiative. Kram’s employees pride themselves in offering excellent client service and high product quality.

Non-metallic wear-resistant materials for mining applications

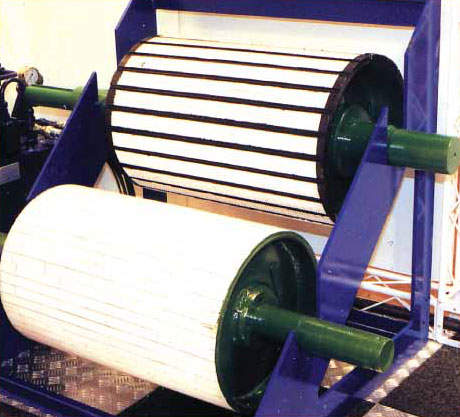

Kram Engineering specialises in supplying and installing wear-resistant materials in high wearing applications such as mining or in specific areas such as chutes, cyclones, pipes, PF burners and conveyor pulleys, etc.

Our competent installers are always available for quality installation of our products on-site or in-house. A complete solution to wear problems is provided using the following products:

- Alumina ceramic tiles (standard and pre-engineered) – alumina ceramics is one of the hardest of all natural substances known to man, ensuring our tiles withstand extremely abrasive conditions. No material can compete on a cost-to-life basis with its extreme hardness and wear resistance

- Epoxy-based wearing compounds – cured epoxy resins possess an outstanding combination of properties including mechanical strength, heat resistance and flexibility, as well as good impact, corrosion wear and chemical resistance

- Silicon carbide (nitride and reaction bonded) – also known as carborundum, silicon carbide is a compound of silicon and carbon

- Cast basalt – formed by recrystallising naturally occcuring basalt rock and forms a finely crystalised glass ceramic of extreme hardness. It provides a resistant long-lasting lining for static plant over which large volumes of abrasive or corrosive materials are passed

- Tungsten carbide – approximately three times stiffer than steel, Tungsten carbide is an extremely strong material for rugged applications

- Chromium carbide – particularly effective where sliding abrasion is present.

- Ultra-high molecular weight polyethylene – an extremely low coefficient of friction allows for outstanding sliding properties

Ceramic-lined cyclones for the mining industry

Kram Engineering manufactures a range of ceramic-lined dense media separating, dewatering and classifying cyclones for use in the mining industry. These products are lined with 92% alumina content ceramic tiles and are extremely cost effective, with tests showing that ceramic-lined cyclones will outlast cast or rubberlined alternatives.

Apart from excellent wear resistance, alumina-lined cyclones have the added advantage of re-usable steel casings once the lining has reached the end of its lifespan. Any size of cyclone can be lined with ceramic tiles in both wet and dry applications.

Ceramic micro grinding media

This specialised product is supplied to the platinum industry. Kram Engineering has agency agreements with some of the world’s top manufacturers of ceramic micro grinding media, ensuring you will receive a quality product.

About Kram Engineering

The brainchild of extraction metallurgist Ferdi Barnard, Kram has gone from strength to strength since its inception in the mid-90s, expanding its reach into a plethora of sectors.

Having successfully managed the company for a fruitful 11 years Ferdi appointed Chris de Bruin as the new Kram’s new managing director. Chris, the company’s former sales director is another extraction metallurgist, with over 15 years experience in wear-resistant linings.