SchuF Fetterolf designs and manufactures a range of valves for mining and mineral processing applications. The valves can be used to control, divert, isolate and sample gases, liquids, slurries and powders.

SchuF specialises in producing valves for the most severe service conditions found in the mining and mineral processing industry. These include valves capable of handling high pressure letdown (to 200bar), high solids content, abrasive materials, corrosive chemicals or a combination of all four.

High pressure acid leach (HPAL) valves

Oxidative leaching processes such as HPAL or Activox (for copper, nickel, cobalt and gold) push every piece of equipment to their limit and therefore require special severe service valves. SchuF provides control, isolation, and feed or drain valves customised according to the specific mineral ore process conditions and the piping/equipment requirements.

Whether it is for an HPAL process (5,400kPa) or a mild pressure (1,000kPa) Activox leaching process, SchuF has an appropriate valve design.

Severe service valve applications

Applications in mineral processing for our severe service valves include:

- Feed and drain valves for pipelines and autoclaves

- Autoclave discharge pressure letdown

- Flash-cooling tower pressure letdown

- Process ore slurry isolation

- Autoclave isolation

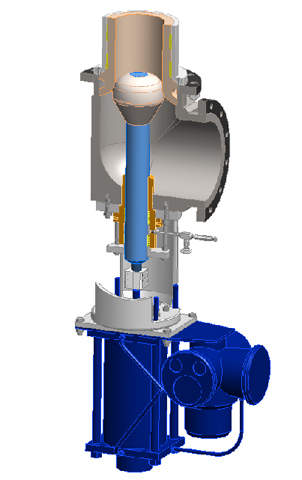

Feed and drain valves for oxidative leaching processes

Feed or drain valves located in or around the autoclave or flash tower must handle severe conditions, including high-temperature acid slurry and high solids content. SchuF provides valves in duplex, hastelloy or titanium (of 1in to 36in and ASME 2500# standard) with custom gaskets, and special coatings for the ram and valve seat. The valves have a number of advantages:

- Fast acting, full-bore flow

- Dead space free drainage

- No leakage to atmosphere

- Fully hardened, diamond-polished piston (extends packing life)

- Automatic crust breaking

- Maintainable on-sie

Severe-service control valves

SchuF provides control valves suitable for pressure letdown, feed and level control in and around autoclaves and flash-cooling towers. Key features include:

- DN 25 (1in) to DN 600 (24in) forged or cast

- Body geometry with constant acceleration to the seat

- Duplex, hastelloy and titanium bodies

- Special ceramic trim

- Single or multistage letdown

- Linear, true equal percentage or SchuF X³ bell curve control characteristic

- Patented trim-protection options

- Easy-to-replace trim parts

Its expertise in material and long-life trim design enables SchuF to minimise the effects of corrosion and scaling common in mineral processing applications.

Isolation valves for mineral processing applications

The isolation of pumps, vessels and other equipment is critical to ensure operational efficiency and safety of mineral ore processing facilities. SchuF provides a range of isolation valves including Y-globe, diverter, gate, angle and high pressure isolation valves. In addition to special body materials and trim, SchuF Y-globe and angle-type isolation valves benefit from:

- Optimised flow-body design – low pressure drop

- Zero leakage to atmosphere

- Tight shutoff to ASME Class VI or API 598

- Dead space free back seating option

- Disc-grinding option to clean valve seat

Alumina production valves

SchuF Fetterolf designs and manufactures a broad range of valves for the production of alumina from bauxite. These include a 45° Y-type (with monobloc body, split-body in line and tank bottom) and 90° angle-type valves (including bayonet valves, three-way valves, check valves and drain and sample valves). They are available in sizes from 2in to 36in and in ASME 150# to 900# classes.