Smart-VOD provides incremental ventilation on demand in underground mines.

Ventilation on demand control fan speed based on the mix of vehicles in the ventilation zone, typically saving 50% – 60% of the energy cost.

Smart-VOD is rolled out incrementally, one ventilation zone at a time. This allows savings from ventilation on demand to be realized without a whole-of-mine deployment, greatly reducing required CAPEX and implementation time.

Ventilation systems for underground mining operations

The majority of underground mining vehicles in use today are powered by diesel motors. Forced air ventilation is required to remove diesel exhaust, blast gases and to reduce the ambient temperature for underground operators.

The common ventilation configuration for underground mines is the use of one or more primary fans generally located above the surface that draw fresh air into the mine down the decline; combined with several secondary fans that force fresh air into the working face of blind headings.

Utilising Radio-frequency identification (RFID) technology Smart-VOD tracks vehicle movement into ventilation zones. Software in the Zone unit determines the aggregate airflow required based on the requirements of each vehicle in the zone. The appropriate drive level for the fan is determined, incorporating the most recent calibration data for the fan and vent bag.

Calibration data is gathered at each ventilation survey. This makes allowance for the vent bag length and condition; both of which change over time.

The power required to run a fan is proportional to the cube of speed. This means that 100% air flow requires full power, 80% Fan speed requires 50% of full power, 75% Fan speed requires ~42 % of full power, and 50% fan speed requires 12.5 % of full power. Small reductions in fan speeds making significant difference to the energy consumption.

The annual energy cost of each secondary fan is substantial, with the cost of operating each fan much more than the purchase price of the fan. Smart-VOD drives substantial energy savings, typically 50% – 60%.

Incremental Ventilation on Demand (iVOD) is achieved by identifying the entry points into a ventilation zone. A Smart-VOD zone unit is installed at the entry point to the ventilation zone and traffic entering is monitored. The air required in the ventilation zone is calculated based on the vehicles in the ventilation zone.

Energy savings can be realised in a single ventilation zone; though there are added benefits as more ventilation-on-demand zones are established.

This incremental approach to ventilation on demand is proving to be easier to implement than a whole-of-mine ventilation-on-demand system and is applicable to smaller underground mining operations.

iVOD drives significant energy and cost savings; as these savings are realised by the operator they can be used to expand ventilation-on-demand throughout the mine. Driving further savings and efficiency.

Wear and tear of ventilation components is reduced when the fan speed is gradually adjusted. Vent bags and fans receive less wear and can expect to be in service for longer.

Ventilation-on-Demand can accelerate the clearance of blast gases, allowing an expediated return to mining after a blast; this may bring forward the re-entry allowing for more extraction.

Each ventilation zone needs adequate ventilation capacity to support peak use. However, its unlikely that every ventilation zone in a mine requires its peak use at the same time. Smart-VOD spreads the ventilation across the mine as required and can be used to cap total ventilation energy to match generation capacity.

Additionally, iVOD contributes to environmental sustainability by minimising waste and emissions, aligning with the industry’s growing focus on sustainable practices.

While most staff at a mine site are focused on ore extraction, Smart-VOD’s focus is on:

- minimizing the energy required for ventilation

- managing ventilation to maximize access to the mine; sequencing the restart of fans after a blast to reduce the time required to clear the mine of blast gasses

- providing through-mine vehicle location tracking in near real-time

Our service drives significant energy and cost savings from day one. Our service has a low capital expenditure and can scale up to whole-of-mine deployments, with the whole-of-mine picture allowing further opportunity for optimisation.

Smart-VOD Zone Units

Each Smart-VOD Zone Unit is designed to operate autonomously and does not require continuous network connectivity. However, when network connectivity is available further features are available:

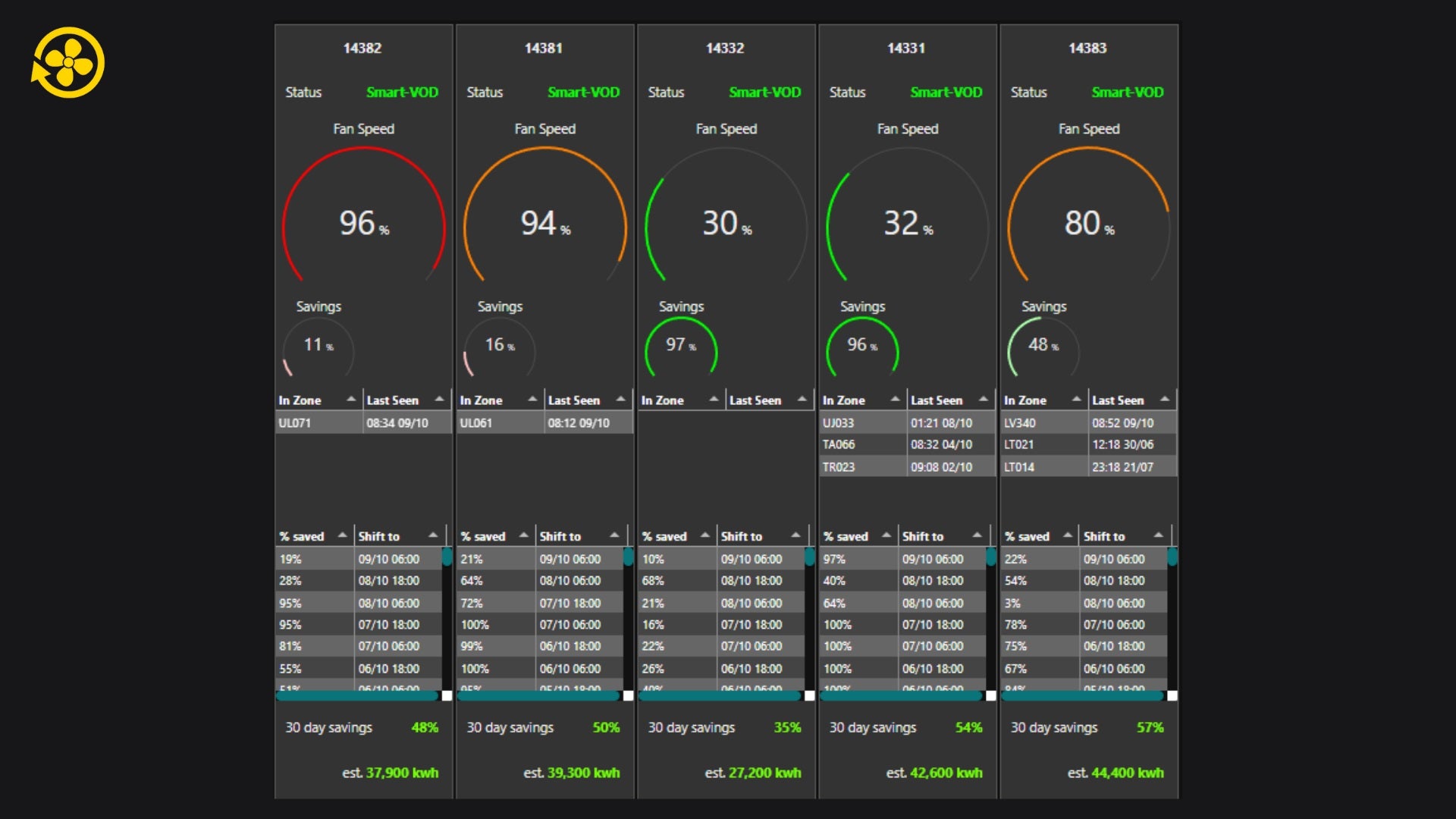

- A centralised mine dashboard showing the status of the ventilation zone along with the savings performance.

- Each Zone Unit advises other Zone Units of vehicle sightings; allowing an ensemble of Zone Units to track vehicle movement accurately.

- Coordination of fan control with other Zone Units and primary fans at a site during clearance of blast gases.

- Configuration updates to Zone and site-wide settings, details of mine vehicles, and updates to business rules.

- Reports on vehicles in each ventilation zone and the corresponding ventilation flow; to demonstrate compliance with legislation ventilation standards.

The Incremental approach

Successful implementation begins with planning; factors to consider during planning are fan size, fan location, depth of drive, length of drive and the price of power.

During the first establishment at a site the zone unit is installed and all underground vehicles are tagged with RFID tags. Any further installation at that site do not require vehicle tagging, making the expansion of the network easier.

When compared to a whole-of-mine ventilation system iVOD is a staged process that allows the mine operator to see benefits with a very short return on investment. iVOD offers more flexibility and adaptability, with fault tolerance and supporting incremental rollout over time.

Variable Speed Drive

Smart-VOD Zone units are most commonly deployed with a corresponding VSD. They can work directly with a conventional fan-starter and can operate both stages of a 2-stage starter unit. The VSD cause less stress on the motors compared to starting direct-on-online, soft starting is also an inherent feature of the VSD.

Additionally, there are circumstances where it makes sense to deploy a Smart-VOD Zone unit without any fan. An example of this would be at the mine portal; tracking what vehicles are underground.

Alternative Configuration – Smart Starter

A Smart-Starter is a DOL starter, single or dual motor, that works with a Smart-VOD Zone unit to control:

- a single fan on or off;

- dual motor fans: both off, one one, or both on;

- a dual-speed fan motor: off, slow or fast

Savings with a Smart-Starter won’t be as high as with a VSD, but the capex is much lower, so the buy-back period is reduced. Smart-Starters’ applicability overlaps somewhat with VSDs, and it’s common for mines to use Smart-VOD with both VSD and Smart-Starter in different mine areas at different development phases.

The Smart-Starter is a joint development in conjunction with SMEC Power & Technology. Smart-VOD has also partnered with SMEC Power & Technology for installation and field support.

Reporting and Data

Smart-VOD gathers substantial amounts of data, about vehicle locations, ventilation and energy usage. For some sites monthly reports on energy savings will be sufficient, while at some sites users will make use of much more of the information gathered.

At a site where only a small portion of the site is using Smart-VOD providing a site-wide real-time dashboard makes little sense; however where most or all of the secondary fans at a site have associated Smart-VOD units a site-wide dashboard can provide a unique view of real-time vehicle locations, loader pickup-sites, and haulage truck cycle times; providing relevant information to the shift-boss and mine manager.