SMI Evaporative Solutions is the largest manufacturer of industrial mechanical evaporation equipment for controlled environment excess water removal. Designed as an alternative to treatments such as desalination, chemical dosing or reverse osmosis, SMI’s evaporation equipment is used to manage water in industries including mining, oil and gas, food processing and power generation.

SMI’s compact evaporation machines are designed to be easily moved between sites and are available as land and water-based solutions. In addition to evaporators, SMI Evaporative Solutions produces software to fully automate the evaporation process.

We produce two types of evaporator – water-fracturing evaporators and water-atomizing evaporators – and can offer a custom service to create a system which perfectly matches your requirements.

Evaporation services

Our primary focus is finding an evaporation solution that is ideally ideally suited for your specific site layout, water chemistry and geographic location. We achieve this by offering a complete service, including:

- Detailed analysis of the site and system recommendation based on findings

- System design and engineering

- Equipment supply including evaporators, pumps and water supply, electrical supply, automation and valves and sensors

- Project supervision

- Complete installation, start-up and commissioning

If our product line does not fully meet your requirements we will create a customized system for you. We take pride in ensuring that our customers are supplied with the perfect system, and we will work to ensure the system we supply is completely suited to your site and needs.

Floating evaporator with submersible pump

SMI’s 420F floating evaporator is ideal for industrial and extreme outdoor applications such as mine sites. A form of water-fracturing evaporator, the 420F consists of a floating unit with a 2hp pump supplied by a variable speed drive to provide between 10gpm (40lpm) to over 65gpm (250lpm).

To ensure the unit cannot be capsized in severe weather, the 420F has plastic pontoons to keep buoyancy, which are filled with closed-cell foam. The water plume height is also kept low to allow longer operation in high winds.

The 420F is built to be sturdy and robust to the elements, and the control panel, motor enclosure, fan blade and manifold are all made in high-quality stainless steel.

To make sure cable splicing is not required, the 420F comes with a 200ft (61m) continuous cord, meaning it can be used on a large surface of water without needing to extend the power cable.

Specific benefits of the floating evaporator include:

- 3,600rpm blade rotation (depending on power supply) to provide optimum water droplet distribution for evaporation

- Average annual evaporation rates between 25% and 60%, with some regions reaching 70%

- Easy maintenance: no weekly cleaning or greasing required

- No pre-filtering, no clogged nozzles due to fracturing technology, or filter cleaning required due to large orifice sizes

- Rugged and durable

- Available with a chemical-resistant coating for corrosive environments

- Automatic cut-off in the instance of residue or severe ice

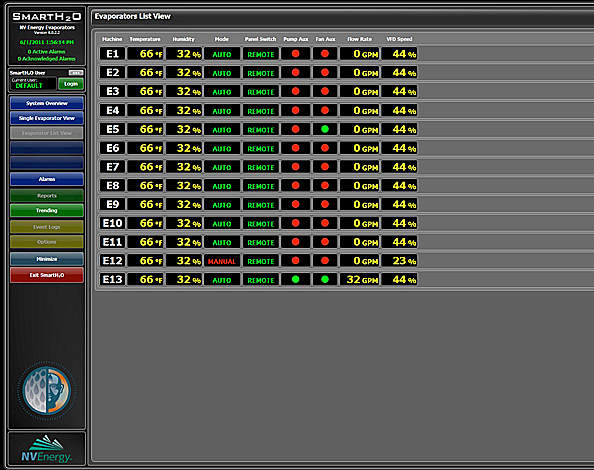

Automation software for evaporators

SMI’s automated evaporation software, SmartH2O, operates the evaporator in response to weather conditions. For sites where the water is corrosive or contains chemicals, we strongly recommend the use of automation software due to the speed and accuracy of its response.

SMI provides custom SmartH2O packages designed to match the equipment and needs of your site. These can be split into ‘Basic’ and ‘Premium’ packages.

A Basic SmartH2O package will stop and start evaporators and pumps in response to changing weather conditions, including wind speed and direction, humidity and temperature. The package typically includes:

- Master control panel

- Weather station

- Mounting pole

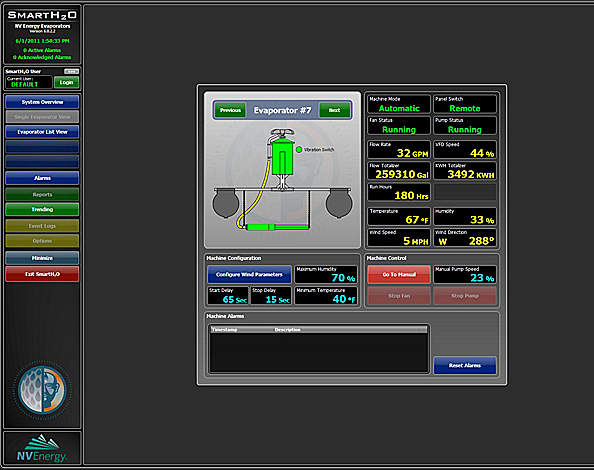

A Premium SmartH2O package operates in the same way as the basic set-up, but allows the user additional control over the equipment. A range of custom features are available, including:

- Sensors and controls programming to allow increased evaporation during suitable conditions

- Data interface to enable communication with site control system

- Monitoring for water and saline levels, rainfall water flow, rate and pressure

- External internet access to allow the downloading of data

- Camera to enable ‘real time’ views of site locations

Custom evaporative solutions from SMI

SMI Evaporative Solutions will be happy to work with you to find the ideal solution to your evaporation needs. Having provided systems for mining companies in the US, Australia, Columbia, Chile, Mexico, Bolivia and others, SMI is experienced with a range of climates. To find out more about our evaporation systems, or to learn how we could help your company, please contact us using the details below.