Sulzer designs and manufactures pumps and agitators. Sulzer’s products are recognised for their quality and reliability, and they are essential to a wide range of applications in the metals and mining industries.

The company’s proactive research and development into fluid dynamics, process-oriented products and special materials supports its customer-focused approach. Industry experience, detailed knowledge of metals and mining applications and an understanding of customer needs has enabled Sulzer to develop innovative and sustainable pumping solutions.

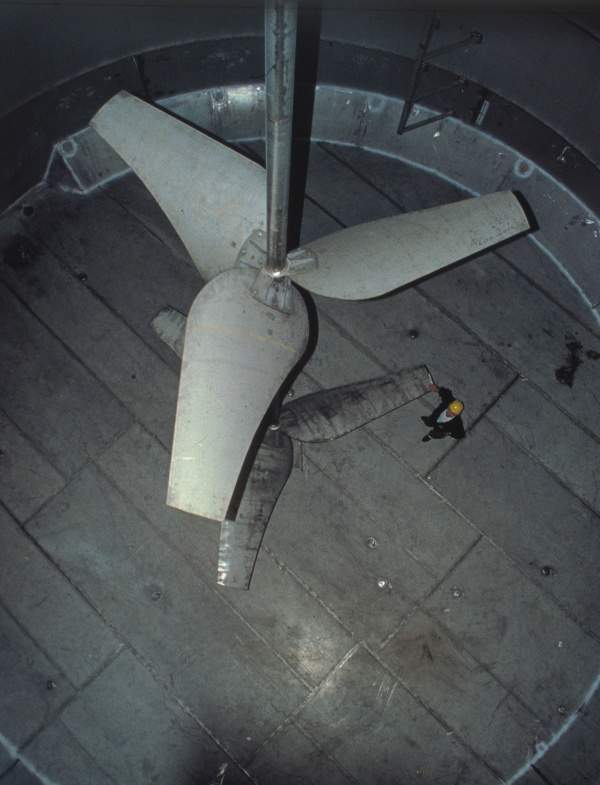

Pump and agitation packages for metal processing

Sulzer supplies complete pump and agitation packages for the mining and metal industries, from clear liquid and light slurry processes, to submersible and dewatering pumps. All pump packages include customer service and support. Sulzer’s comprehensive portfolio of innovative pumps and agitators is designed in accordance with the latest standards issued by ISO, API and ANSI.

The combination of top-quality materials and tailor-made hydraulics ensures that the customer receives a reliable pump process and maintenance-free operation.

Sulzer offers pumping and mixing solutions for corrosive and abrasive liquids, and coating solutions to protect machinery from the high temperatures and wear of metal processing. The company’s expertise includes the production of alumina, aluminium, copper, nickel and zinc.

Corrosion-resistant pumps and mixers

Research and development is a priority for Sulzer. The company works closely with its customers to develop pumps and mixers that fit their operations. Sulzer’s foundry and metallurgical knowledge are key to its development of equipment with a strong resistance to corrosion and wear.

Sulzer produces various grades of corrosion-resistant cast alloy steels, martensitic, austenitic and duplex. Pumps can be manufactured from special materials like titanium and Hastelloy, and also AVESTA 654 SMO* material, for the most corrosive applications.

*AVESTA 654SMO is a trademark owned by Outokumpu Stainless, which has granted Sulzer a licence to produce this material.

Pump product development

Selecting the best pump system for the job can significantly boost the efficiency of an operation and Sulzer can help customers do that. Sulzer’s existing customers have gained from improved reliability of their process-runs and some have changed from stand-by pump practices to single pump systems.

Sulzer offers customers:

- The largest portfolio of innovative process pump and mixer products, including complete water and wastewater treatment applications

- Tailor-made product solutions

- Greater hydraulic excellence

- Environmentally and economically sustainable solutions

- Lower power consumption

- Experience in managing a diversity of process liquids and application environments

- Extended run times on equipment and longer periods between failures

- Interchangeability between common parts to lower capital costs and increase productivity

- Optimised selections, guidelines and project management

- Large reference list of installed base and mill contacts network

- Continuous equipment development for excellent performance

Excellent service on your doorstep

Sulzer has 170 sales offices and global service centres that operate around the clock to ensure fast response times and quick deliveries. The company’s global delivery and customer service network includes an advanced service centre and parts processing centre network, which provides qualified services for the entire product lifecycle, day and night.

The company’s comprehensive service offerings include troubleshooting, energy audits, fast delivery programmes, pre-configured retrofit products and various service kits.

Sulzer can service existing equipment with original spare parts, including non-Sulzer products like:

- Scanpump

- ABS

- Ahlström

- Serlachius

- Enso

- API Sonesson

- Gothia

- JMW

- Warren

Sulzer offers sustainable solutions by minimising the company’s environmental footprint and delivering a measurable return on investment. Sulzer’s product portfolio demonstrates the highest attainable efficiency level in the market, offering customers the most eco-efficient product solutions.

Quality products and customer service

Sulzer’s pumps and mixers are renowned for their sturdy designs. The latest manufacturing technology and strict quality control procedures ensure high levels of efficiency and performance over the full range of process conditions.

All of Sulzer’s process pumps are rigorously tested, and customers receive high-performance pumping and mixing equipment, exceptional customer service and lifecycle value.

Customer satisfaction is paramount to Sulzer and feedback is used to improve products and services. Quality assurance begins at the contract review and continues throughout the process in a planned and controlled manner. All manufacturing sites are certified according to standards ISO 9001:2008 (quality), ISO 14001:2004 (environment) and OHSAS 18001:2007 (health and safety).