ABB’s approach covers the complete value-added chain, from your mine to the product you market. We excel at merging equipment, skills and services to develop a complete customized solution that strengthens your entire operation regardless of project size. ABB’s capabilities combined with its global and local resources offer integrated power, control and information solutions.

Electrification and plant engineering

The efficiency of an industrial plant is influenced by its major mechanical and electrical installations, appropriate planning and engineering. We ensure the selection of the right technologies and products, their correct dimensioning, compliance with environmental conditions as well as the implementation of industry-dedicated smart solutions. All of this leads to substantial savings in investment and energy consumption adding up to a significant enhancement in a plant’s economy over its lifecycle.

Viewed as an integrated entity, the plant’s infrastructure includes items like optimized substation and electrical room layouts, cable engineering, grounding systems, fire detection and protection, air-conditioning and ventilation systems, communication systems and much more. ABB’s electrification solutions are engineered for safety, flexibility, security and the highest operational availability to keep your plant running day and night.

Power distribution

We offer the broadest range of high, medium and low voltage equipment for switching and distributing electrical power. Solutions are engineered for safety, flexibility and security to keep operations running day and night. This includes emergency power generation and UPS, prefabricated sub-stations, power factor compensation and harmonic filtering equipment, switchgear and transformers. ABB provides you with state-of-the-art technology to exceed today’s rigorous demands.

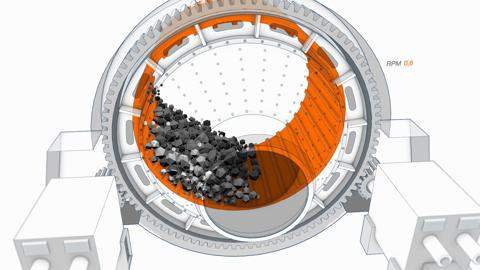

Drives applications

Selecting the right drive system for a particular application requires knowledge and experience within the process environment. ABB manufactures motors and drive systems from sub-kilowatt to the megawatt ratings of gearless drives for the largest SAG and ball mill applications. ABB combines its extensive industry knowledge with its application expertise to select the most economical drive solution for your particular, often unique circumstances. From single/dual pinion and high pressure grinding rolls to material handling, pumping and conveying systems, we continually strive for the highest availability, productivity and energy efficiency your operations can achieve.

Process control and instrumentation

Our process control solutions provide easy access to the process, production, quality and business information – from the most remote locations to corporate headquarters. Whether you are building a greenfield plant, extending or modernizing an existing plant, ABB provides tailored automation solutions that use real-time data – enabling constant monitoring and analysis of your process combined with improved asset availability. ABB also provides a wide range of instrumentation products for mining and mineral processing.

Integrated mine operations and remote control rooms

To increase production, improve profitability and reduce operational risks, companies require an operations management software platform which improves information flow and visibility across organizational silos and optimize business processes from mine to market. ABB is uniquely positioned to bring together industrial enterprise software spanning process control, production management, operational planning and optimization, work and asset management and backoffice corporate functions. As one of the leading providers of software to mining and mineral processing worldwide, ABB is on the forefront of technologies across the mining lifecycle that can help drive significant business value.

Service

Any equipment failure can seriously affect your plants productivity and profitability. To ensure that your investment is protected and to optimize asset performance, ABB has developed a concept based on the need to minimize operational risk and increase system availability. Our integrated long-term service agreement combines one or more service products in a simple customized agreement. You can choose the services that meet your site-specific requirements for preventive, predictive and corrective maintenance: field services; spare parts; services; remote services; training services; special services.